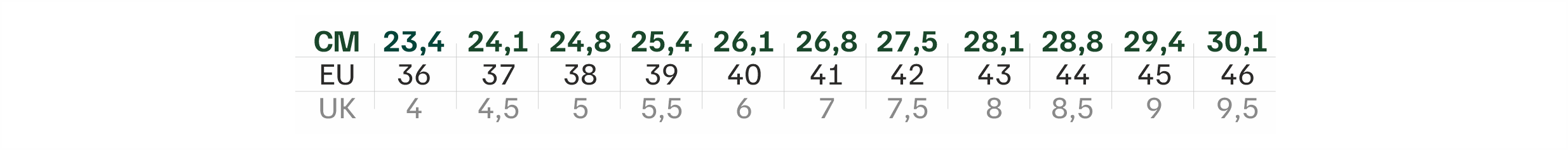

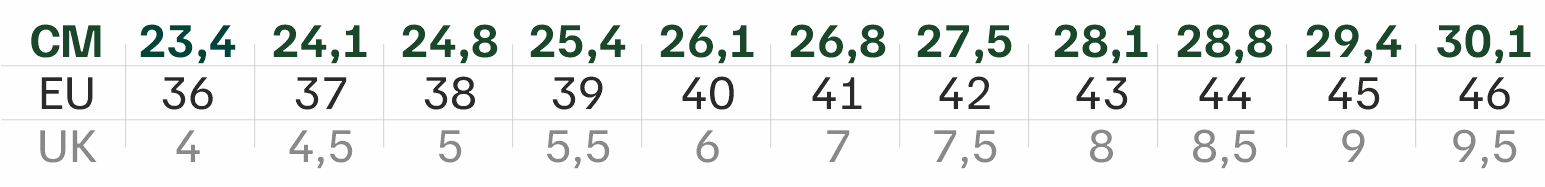

WHAT SIZE DO I PICK?

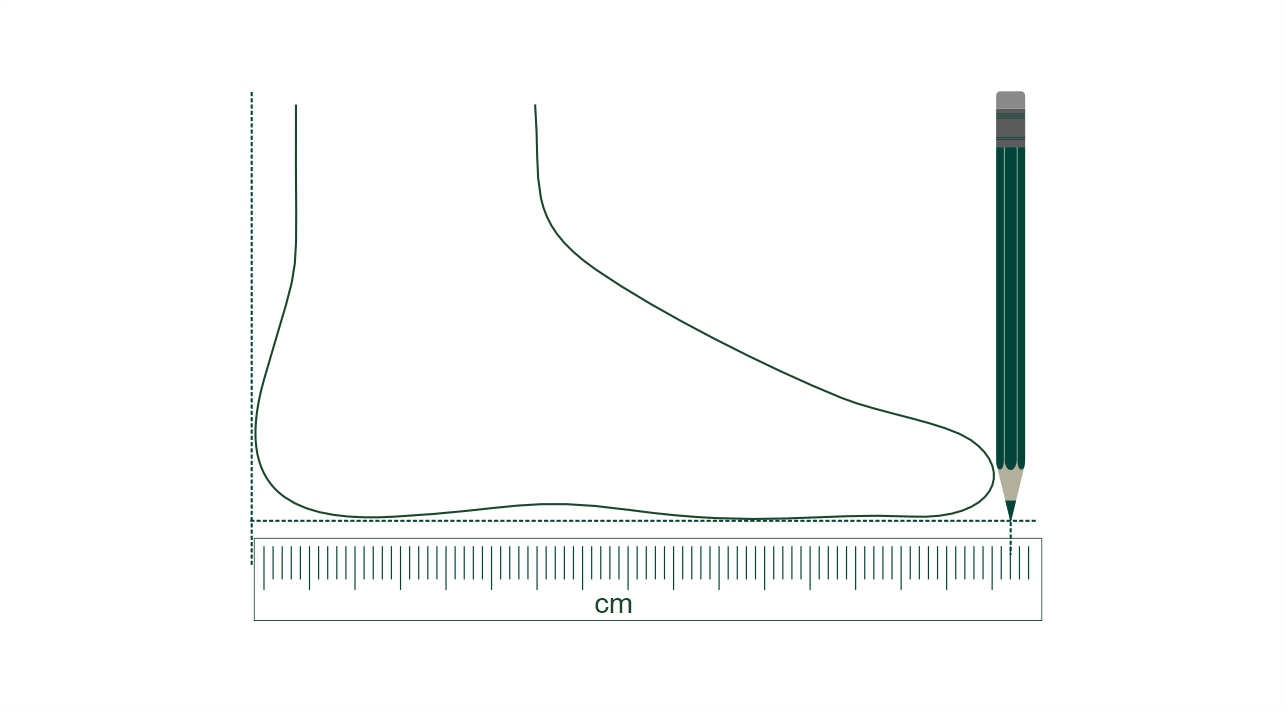

SNEAKERS & SANDALS

If you have doubts between two sizes, we recommend the smaller one.

BELT

Belt measurements range from 70 cm to 140cm waist.

To select the correct size, you must measure your waist and choose the size closest to your waist size.

Example: If you select 90 cm it is because your waist measures exactly or close to 90 cm.

Then we take care of adding an extra 20 cm for its correct functionality.

CAPS

Unisex and Unisize - Coconut shell button to adjust the cap in 3 size positions